Why is 3D Printing the Next Big Thing?

3D printing has existed for several years, but it is only now becoming commercially viable. Many in the architectural and engineering sectors point to it as the next big thing.

Bringing ideas to life is the biggest task facing architects and engineers. As a trained professional, your aim is to help untrained people understand where you’re going. Anybody who’s pitched for design work knows how difficult this can be. Without the right tools, you’re restricted to describing the project and hoping others can visualise it.

For centuries, architects and engineers used 2D drawings to demonstrate their intentions. The rise of computer-aided design made this job easier. Designers could use more data, thus creating accurate drawings quickly.

These software packages evolved further over time. Today, we have digital design software that allows you to model 3D structures in photorealistic styles. Virtual reality has changed the way you present to clients, and other technologies have emerged to help you along.

3D printing is one such technology, and it has its uses in architecture and engineering. It opens the door to creating realistic scale models of your designs. However, until recently 3D printing was a costly endeavour. As a result, many in the sector still don’t use it.

However, 3D printing is the next big thing. Read on to find out why.

What is 3D Printing?

Also known as additive manufacturing, 3D printing allows you to turn digital models into solid objects. This requires the use of a digital design software package or a special scanner.

The basics are pretty simple. You build your model digitally using your software. Think of this model as a “mould”. You’ll be using it to manufacture an item, so it has to be accurate.

With your model in place, you transmit the data to a 3D printer. This then uses the data to create the model in real life using various materials.

You can also use a special scanner. This allows you to take an existing real-life object, and scan its information into your software. The printer then creates replicas of this object, making it useful in manufacturing.

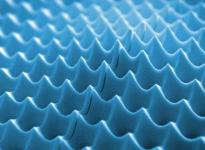

3D printing uses an additive process, instead of the traditional subtractive process. With subtractive modelling, you take a material and remove portions until it meets your requirements. In additive modelling, the end object gets built in layers, without the need for material removal. Each layer is a thin horizontal slice, and they build on top of one another to create the object.

Anything that challenges the traditional faces some obstacles. 3D printing is no different. Many point to the cost of the machinery, without looking at the many benefits it provides. Let’s look at these benefits so you understand why 3D printing is the next big thing.

The Benefits of 3D Printing

You may have read about the benefits of 3D printing in the manufacturing sector. However, it provides just as much to architects and engineers too. Here’s eight of the biggest advantages.

Benefit #1 – Less Material Waste

Think about the last time you built a scale model for a client. You carefully cut and pasted your materials to create a model that looked just right. In doing so, you left a whole lot of waste behind. You had to take away parts of materials to get them into the right shape. For example, you may have had to carve and sand a piece of wood so it matched your design.

The point is that you had to buy more materials than you really needed to build your model. A huge amount of what you bought ended up in the bin or getting recycled. That’s all money out of your pocket as a result of the subtractive process.

3D printing’s additive model means that you don’t have to buy more materials than you need. Instead, you build models that are just as effective, without all of the waste. Not only does this save you money on material purchases, but you also spend less on disposal costs.

On top of that, producing less waste makes you more environmentally-friendly. This helps when you’re pitching for projects. You'll impress clients with your concern for the environment. Better yet, you'll demonstrate your commitment to building environmentally-friendly structures.

Benefit #2 – Better Client Visualisation

When pitching for a project, you need every tool at your disposal for helping clients to understand your vision. Flat, 2D drawings don’t cut it. They’re full of impenetrable measurements that don’t highlight the scale of the undertaking.

That’s why most of you use a combination of 3D models and modern technologies to do the job. Digital design software offers a computerised representation of the project. Virtual reality design software takes it a step closer to real. However, even a virtual reality model is still a simulation. It’s not something that your clients can touch and feel.

That’s where traditional 3D models come into play. A good scaled model is another way for you to communicate your intentions to your client. You can also use it to show how your design ideas look in real life. 3D printing allows you to create detailed models based on your digital designs. As a result, it eliminates the guesswork involved in handcrafting them.

Benefit #3 – Cheaper Item Creation

Even though the technology has become more affordable, many still balk at the cost of 3D printing. This isn’t the case in the manufacturing sector. When creating lots of simple items, 3D printing really comes to the fore. Companies like Converse made huge cost savings when they adopted the technology.

On the face of it, this suggests that the technology is best suited to creating the same object over and over again. This doesn’t make it less useful to architects and engineers.

Cost savings through 3D printing come in several ways. For one, the time saved on building the model benefits you. Instead of spending time and money on manual model building, you can rely on the printer to generate a real model based on your digital design.

Secondly, don’t underestimate the amount of repetition that goes into your work. A structure may require several decorative items as well. For example, you may need some trees to line the exterior, or need to print an array of columns. This all cost money to make yourself, plus there’s the previously mentioned material waste to account for.

Take these indirect costs into account and printing becomes a money saver. These savings will only increase over time. Cheaper materials and improved techniques will both add to the money you save. Plus, you can use the models you create in your software as many times as you want.

Benefit #4 – More Complex Designs

Think again about creating models manually. Every delicate piece of design work presents a problem. Each little contour requires sanding and chiselling, which all takes times that you could spend better elsewhere.

The simple fact is that creating your digital models in real life is not easy. You’ll spend hours trying to get the particulars right if you want to present the best possible model to clients. This leads to fatigue, which results in mistakes. Sometimes, you may exclude important details to get the scale model built on time.

You don’t have to worry about any of this with 3D printing. Your ability to create complex solid geometry yourself no longer limits you. Instead, you can rely on your printer and digital design software to do the work for you. This leads to models that represent your vision with greater accuracy.

Benefit #5 – Minimising Risk

Handling risk is one of the key purposes of building scale models. While 3D models help calm clients’ fears, they still want to see that everything works as you claim it will. A scale model allows them to examine the reality, as well as the virtual representation.

With a 3D printer, you minimise risk even more than you would when building scale models by hand. For one, you eliminate the possibility of human error. Your digital design software should catch any miscalculations you make before you start making the model. When doing it manually, those miscalculations lead to mistakes when creating your parts. These mistakes prevent things from fitting together properly. This means you have to go back and figure out where you went wrong.

With 3D printing, the scale model should work as long as the digital model works. If it does come out wrong, you know you have a problem to fix with the digital design. You end up with an accurate model that shows clients how much risk they have to deal with.

Benefit #6 – Material Choice

Some architects and engineers avoid 3D printers because they’ve seen what early examples of the technology produced. There’s some validity to this. Early 3D printing resulted in rough and pixelated models. You had to deal with limitations when it came to materials too. None of this contributes to impressing clients when pitching or presenting.

But the technology has come a long way since those early days. You now have a choice of a vast array of materials at your disposal. Polyamide is among the most popular, and it creates the smooth objects you’re looking for. However, you can also incorporate brass or steel into your models. You can even add transparency to create an even more realistic depiction of windows and the like.

Advancements in the technology have done away with any early impressions. Today, 3D printers offer greater versatility and the ability to use several materials when creating scale models.

Benefit #7 – Simple Editing

Have you ever built most of a scale model, only to find one mistake has ruined everything? By that point, you may have built most of the model, and the piece may even be inaccessible. You’re left with no option but to scrap the model and try again.

3D printers don’t completely eliminate mistakes. However, they make them easier to deal with. If you spot a mistake with your model, you need only open your digital design software and correct it. Then you can reprint the model without wasting too much time.

With traditional model building, you salvage what you can from the model and start again. You have to repeat all of the tasks you’ve done already. Plus, you waste even more material while building.

Benefit #8 – Fewer Tools Required

You may need all sorts of tools for traditional modelling. Every chisel, hammer, and sander costs money to buy. You also have to maintain them to get the most out of them.

A 3D printer may cost more than any one of these traditional tools. However, it’s also the only tool you’ll need to create scale models. As long as you maintain it well, your printer takes away much of the cost and work involved in creating your models.

The end result is a model that requires less tooling at each stage. Better yet, you get the end product quicker, and use fewer tools and parts in the process of making it.

Conclusion

Every new technology brings with it a number of doubters. There are many in architecture and engineering who may not believe that 3D printers can help them.

However, the benefits are undeniable. With 3D printing, you can create more complex models quickly. The technique produces less waste than regular modelling. This boosts your firm’s environmental profile and saves money. You don’t need to buy as many materials or tools, which saves you money over the long run. Better yet, you have a choice of materials with modern printers, plus you can handle any mistakes easily.

3D printing is the next big thing because it makes you more efficient. As costs continue dropping, you’ll see more in the sector adopting it to create their models. Don’t fall behind. The models you create with a 3D printer may be the key to helping clients visualise your ideas.

Of course, you need to know your way around your modelling software before you can use your printer to its fullest. That’s where ArchiStar Academy can help. We offer several digital design software packages at industry-best prices. Furthermore, ArchiStar Academy provides courses on several software packages. They cover everything from the basics through to more complex design work.

If your firm needs to prepare for using a 3D printer, contact ArchiStar Academy today. We’ll equip you with the tools you need to maximise your investment in this new technology.

ArchiStar Academy offers several courses across the spectrum of digital design software. You’ll develop your skills, allowing you to create more accurate and functional models.

Please don’t hesitate to get in touch with Archistar Academy today if you have any questions.

If you would like to share your thoughts on our blog, we’d love to hear from you!

Get in touch with the ArchiStar Academy [dev] community via Facebook.

Posted on 20 Jan 2020

![ArchiStar Academy [dev] logotype](https://academy.archistar.io/images/archistarr-academy.png)